Features of our Process refrigeration products

- Two stage/three stage open/cascade systems based on the temperature applications.

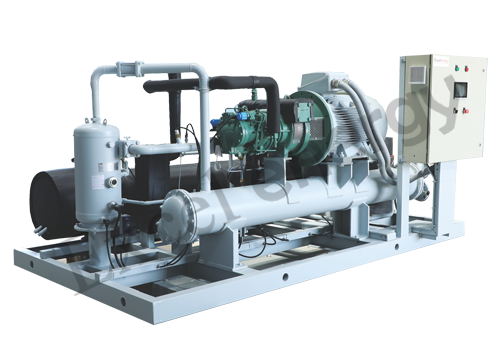

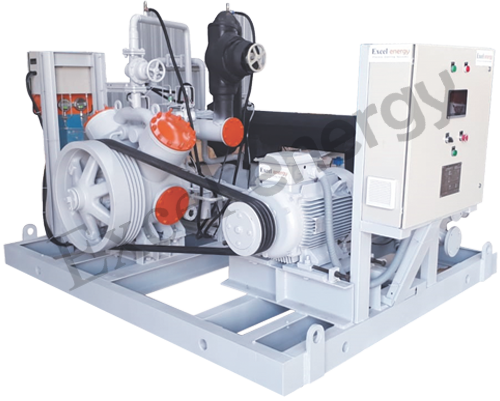

- Reciprocating, Screw compressor with Single and Twin-screw technology.

- Low refrigerant charge using highly efficient heat transfer tubes and Plate heat exchangers.

- Step-less variable speed capacity control system meeting process demand accurately.

- Fully automated controls using flexible PLC Programs capable of handling load fluctuations for efficient operation.

- Automated In-built oil management system with best oil separation technologies.

- Wide range of natural and eco-friendly refrigerants.

- Compact Skid Mounted package for wide range of applications.

- Suitable for Dual Temperature mode to use the system for different Process reaction temperatures.